-

ZJN company has passed the certification of "Specialized, Fined, Peculiar and Innovative" small and medium-sized enterprises in Henan Province in 2021

The list of " Specialized, Fined, Peculiar and Innovative " enterprises in Henan Province in 2021 was announced. A total of 928 enterprises in the province passed the evaluation, of which 56 enterprises in Jiaozuo City were on the list, including Jiaozuo ZJN environmental protection equipme

2021-05-0768 -

Welcome the leaders of China Merchants bureau to investigate ZJN company

A few days ago, the leaders of China Merchants bureau made a special trip to investigate Jiaozuo ZJN company.The leaders carefully understand the patent technology, product situation, sales situation, customer type and raw material purchasing information of the company.

2021-04-2385 -

Chongqing Municipal Sludge project successfully discussed

On April 19, 2021, in a friendly and peaceful atmosphere, the cooperation project between ZJN company and Chongqing municipal sludge drying was successfully discussed. The first batch of equipment will be delivered in the near future.

2021-04-2188 -

Municipal sludge dryer easily realizes "four changes"

The municipal sludge dryer uses heat energy to send the dewatered sludge into the dryer and contact with hot air to dry the sludge.Municipal sludge dryer easily realizes "four changes".

2020-12-1494 -

Jiaozuo ZJN donated epidemic prevention materials to help Sanyang No.1 Middle School

In May 20, 2020, Yue Shengwen, general manager of Jiaozuo ZJN donated 10000 masks and 80 bottles of disinfectant gel materials for the first middle school of Sanyang Township, Wuzhi. Lvyinsheng, deputy director of Wuzhi County Civil Affairs Bureau and Li Xibao, President of Sanyang No.1 middle schoo

2020-12-14116 -

Heat source analysis of drying equipment

The hot air furnace is the heat source of drying equipment. Drying equipment in drying materials need to consume a lot of heat source, then the heat source can be coal, biomass fuel, fuel oil, gas and so on.

2020-12-1471 -

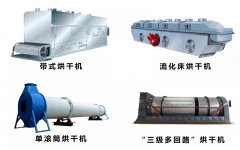

Introduction and comparison of four common dryers

Belt dryer,Fluidized bed dryer, Single drum dryer and "Three-cylinder multiple loop" dryer,Introduction and comparison of four common dryers.

2020-12-1469 -

How to distinguish the various dryers on the Internet?

Different drying equipment is used in different drying fields. When selecting drying equipment, manufacturers must determine the appropriate drying process according to the actual material characteristics (moisture content, viscosity, water molecular structure, particle size, acidity and alkalinity,

2020-12-14172 -

What is the significance of biomass fuel as heat source of drying equipment?

What is the significance of biomass fuel as heat source of drying equipment?Biomass fuel is mainly made from agricultural and forestry wastes (such as straw, bagasse, sawdust, etc.) as raw materials through a series of processes such as crushing, mixing, extrusion, drying and so on.

2020-12-14144 -

Future prospects of sludge dryer equipment remain optimistic

After drying, the sludge can be used for energy, construction, activated carbon adsorbent and so on, which can effectively cultivate and develop the innovation ability of enterprises. Sludge drying equipment is the equipment that uses waste to produce renewable energy, which promotes the development

2020-12-14193

-

About +

About us Contact us -

Solution +

Sludge Dryer Steam Dryer Pulp Dryer Dregs Dryer Waste Heat Utilization Dryer Dryer For Mining,Metallurgy And Chemical Industry Auxiliary Equipment Of Dryer -

Case Video +

Sludge dryer case video steam dryer case video pulp dryer case video dregs dryer case video Waste heat utilization dryer case video Dryer For Mining,Metallurgy And Chemical Industry case video -

News +

Company News Industry News Technical Information