Waste Heat Utilization Dryer

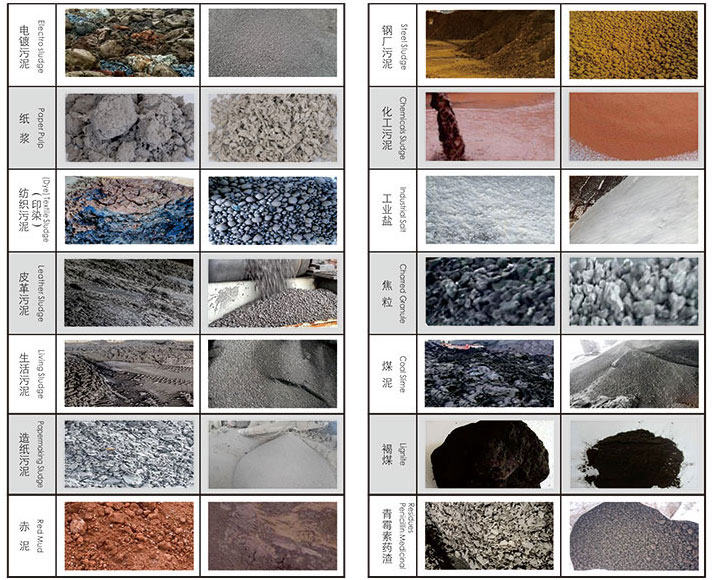

It is suitable for drying high humidity and high viscosity sludge such as electroplating sludge heavy me

Widely used in electroplating enterprises me

24 Hours Free Consultation Hotline

+86-176-3914-6338

Product Details

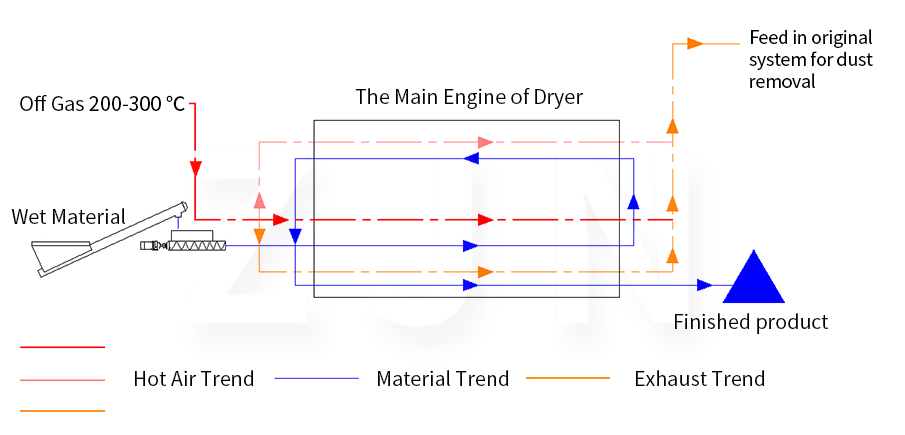

Waste heat utilization dryer production line mainly includes drying host, conveying device and dust removal equipment ( Bag filter, cyclone, etc )、 Induced draft fan, feeding device, discharging device, instrument, etc.

Three stage multi loop dryer for waste heat utilization ( Patent No. 2011200498127 ) It is a national patent technology independently developed by ZJN environmental protection equipment. The waste heat of boiler flue gas can be used as heat source in this process, which is generally used to treat industrial solid waste with high humidity and high viscosity ( dangerous ) The waste sludge is dried. Make full use of the waste heat resources of the enterprise, turn waste into treasure, so as to greatly reduce the heat cost of the dryer. And it's fixing the industry ( dangerous ) When the waste sludge is dried, the dust in the flue gas will be absorbed by the high humidity sludge, and some harmful gases can also be removed by chemical reaction with the alkaline sludge. In this way, not only the waste heat of boiler flue gas is used, but also the dust and harmful gas are indirectly treated, so that the enterprise can effectively achieve "ultilize everything", and get more at one stroke, with remarkable energy-saving effect.

Waste heat utilization and drying technology can effectively meet the needs of waste gas utilization, energy saving and environmental protection. ZJN can provide customized design services according to the daily output, moisture content, waste heat temperature and other needs of users. Scientific and reasonable waste heat utilization technology and sludge drying scheme have been recognized by many users.

1. The equipment parameters are flexible and controllable. According to the needs of materials, we can scientifically design the air volume, wind speed, wind direction, temperature and other equipment parameters in the drying process.

2. Scientific way of water vapor discharge. The whole drying process is divided into three drying stages, the steam in the cylinder is discharged by stages, the material is dried by stages, and the drying rate is dynamic.

3. Special feeding mode. A special reciprocating drying mode is adopted for the materials in the equipment barrel, with three steps and two steps backward. The material drying stroke is effectively extended and the material storage capacity is large.

4. Energy saving, environmental protection, clean and dry. The waste heat utilization drying technology makes full use of waste heat resources, and combines with ZJN low-temperature drying process to greatly reduce the operation cost of the equipment. Moreover, the equipment has good sealing performance, no dust overflow and good working environment.

It is suitable for drying high humidity and high viscosity sludge such as electroplating sludge, heavy metal sludge, leather sludge, chemical sludge, printing and dyeing sludge, textile sludge, pharmaceutical sludge, papermaking sludge, sewage sludge, municipal sludge and industrial hazardous waste sludge.

Widely used in electroplating enterprises, metal processing enterprises, paper enterprises, textile printing and dyeing enterprises, pharmaceutical factories, sewage treatment plants, chemical enterprises, pharmaceutical enterprises and other industries.

Most of the waste heat of boiler flue gas is about 200 degrees. Under normal circumstances, it is difficult to effectively dry sludge at such a low temperature. The research and development of drying technology for ZJN waste heat utilization makes low-temperature drying a reality, and also provides a new blue chart for enterprises to realize energy conservation and emission reduction.

The waste heat utilization dryer adopts special "three sleeve" structure mode, positive and negative material lifting and guiding system and "W + s" feeding process, which greatly improves the heat energy utilization rate and drying efficiency of the equipment. The material and hot air travel exceeds the design length of the equipment by several times. It can save the floor space and fully dry the materials, avoiding the traditional drying Single drum drying equipment covers a large area, has the disadvantages of large heat loss, small processing capacity, high energy consumption and uneven drying of materials.

The comprehensive economic benefit of waste heat utilization dryer is more than several times of that of traditional drying equipment. At present, the technology has become more and more mature through continuous improvement of real energy saving, and has gradually gained a firm foothold in the market, and has been praised and recognized by many customers.

Customer Case

Waste heat utilization dryer case video

- Heating Mode: boiler flue gas, waste heat steam (130 °- two hundred ° C; Air volume (20000-200000)

- Processing Capacity: 20-150t / D / set

- Suitable Material Moisture Content: 60% - 80%

- Moisture Content Of Finished Product: 20% - 40%

SOLUTION

-

About +

About us Contact us -

Solution +

Sludge Dryer Steam Dryer Pulp Dryer Dregs Dryer Waste Heat Utilization Dryer Dryer For Mining,Metallurgy And Chemical Industry Auxiliary Equipment Of Dryer -

Case Video +

Sludge dryer case video steam dryer case video pulp dryer case video dregs dryer case video Waste heat utilization dryer case video Dryer For Mining,Metallurgy And Chemical Industry case video -

News +

Company News Industry News Technical Information