Auxiliary Equipment Of Dryer

Heating equipment dust removal equipment conveying equipment and control equipment.

Heating EquipmentCoal fired hot air furnace gas-fired hot air furnace oil fired hot air furnace coal-fired and gas-fired hot air furnace oil fired and gas-fired hot air furnace.

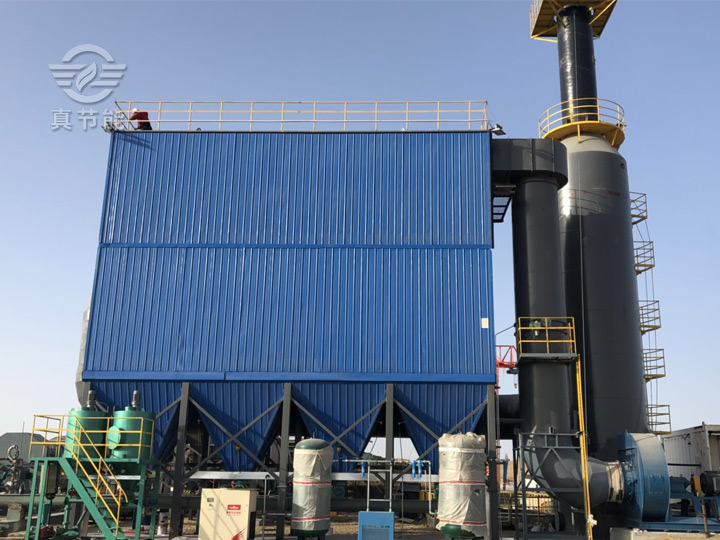

Dust Removal EquipmentBag filter、cyclone、scrubber.

24 Hours Free Consultation Hotline

+86-176-3914-6338

Product Details

The auxiliary equipment of ZJN dryer includes heating equipment, dust removal equipment, conveying equipment and control equipment. The heating equipment includes coal-fired hot air furnace, gas-fired hot air furnace, oil fired hot air furnace, coal-fired and gas-fired hot air furnace, oil fired and gas-fired air furnace; Dust removal equipment includes bag filter, cyclone filter and scrubber. Product customization: according to the nature of the material, processing capacity, custom-made for the customer's dryer equipment.

Gas and oil dual-purpose hot air furnace integrates natural gas, liquefied gas and other gas fuels with gasoline, diesel and other liquid fuels. The equipment can burn both gas fuel and liquid fuel independently. One boiler can be used for two purposes, with good fuel adaptability, simple and flexible adjustment, safety and reliability.

The coal and gas dual-purpose hot air furnace integrates the combustion mode of coal / biomass fuel and gas, which can burn both gas and coal / biomass fuel. One boiler can be used for two purposes, with good fuel adaptability, simple and flexible adjustment, safety and reliability.

The coal-fired hot air furnace is based on coal and air as the medium. It can be used for 24 hours continuous combustion and heating, with high thermal efficiency and simple and convenient operation. It can be widely used in metallurgy, machinery, building materials, chemical industry and other industries. The coal-fired hot air stove can be customized according to the customer's needs. In addition to coal combustion, the coal-fired hot air furnace can also burn biomass fuel.

Natural gas hot air furnace uses natural gas, liquefied gas and other gases as fuel, air as heat carrier, and forced circulation by fan to achieve good combustion effect. The heating produced is mostly used for drying materials.

Bag filter is a kind of dry dust filter. It is suitable for collecting fine, dry and non fibrous dust. The filter bag is made of textile filter cloth or non-woven felt. The filtering function of the fiber fabric is used to filter the dusty gas. When the dusty gas enters the bag filter, the dust with large particles and large proportion will settle down due to the effect of gravity and fall into the ash hopper. When the gas with small dust passes through the filter material, the dust will be retained and the gas will be purified.

The structure of bag filter is mainly composed of upper box, middle box, lower box (ash hopper), ash cleaning system and ash discharge mechanism. Compared with similar products, the dust removal efficiency is higher, generally more than 99%; It can be used for dust removal of various industrial furnaces and drying equipment to reduce the emission of air pollutants; It has the advantages of simple structure, low cost, convenient maintenance and operation.

Cyclone is a kind of dust removal device. Its dust removal mechanism is to make the dust laden air flow rotate, separate the dust particles from the air flow by means of centrifugal force and trap them on the wall, and then make the dust particles fall into the ash hopper by means of gravity.

The cyclone dust removal structure is composed of air inlet pipe, exhaust pipe, cylinder, cone and ash hopper.

The scrubber is a new product of the market factory, which is used for gas purification and treatment. It is widely used in the treatment of industrial waste gas purification, desulfurization and dust removal, and the purification effect is very good. For the gasification process, gas washing is inevitable, no matter what gasification technology is used in this unit operation.

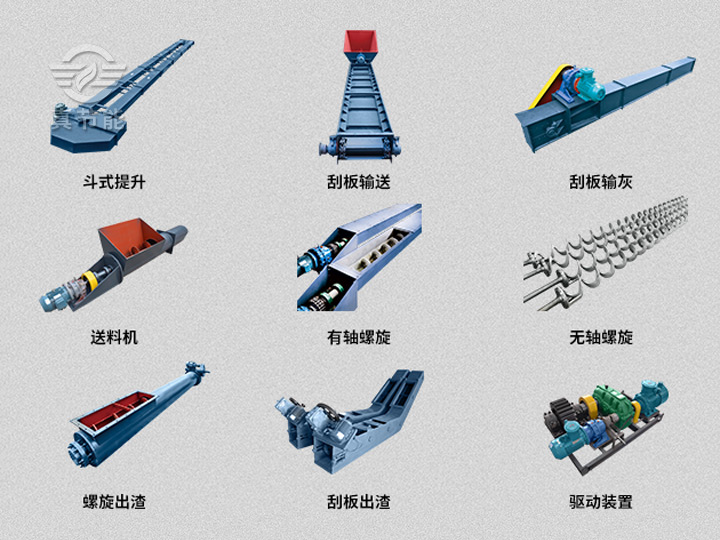

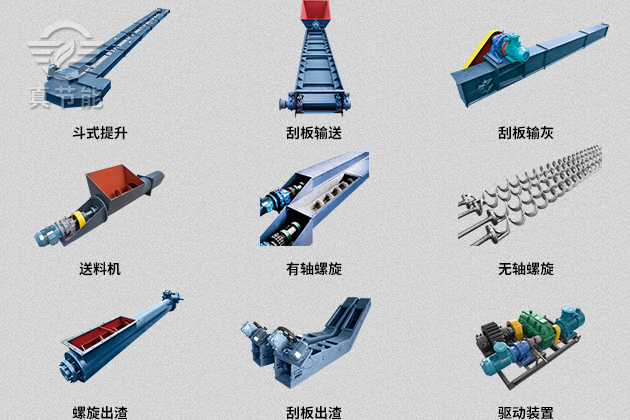

Other auxiliary equipment of true energy saving mainly includes scraper conveying, axial screw conveying, axial screw conveying, belt conveying, bucket conveying, feeder, spiral slag discharging, scraper slag discharging and driving device.

The control cabinet is to assemble the switchgear, measuring instruments, protective appliances and auxiliary equipment in the closed or semi closed metal cabinet or on the screen according to the requirements of electrical wiring. Its layout shall meet the requirements of normal operation of the power system, facilitate maintenance, and do not endanger the safety of people and surrounding equipment. During normal operation, the circuit can be turned on or off with the help of manual or automatic switch. In case of fault or abnormal operation, cut off the circuit or give an alarm with the help of protective appliances.

SOLUTION

-

About +

About us Contact us -

Solution +

Sludge Dryer Steam Dryer Pulp Dryer Dregs Dryer Waste Heat Utilization Dryer Dryer For Mining,Metallurgy And Chemical Industry Auxiliary Equipment Of Dryer -

Case Video +

Sludge dryer case video steam dryer case video pulp dryer case video dregs dryer case video Waste heat utilization dryer case video Dryer For Mining,Metallurgy And Chemical Industry case video -

News +

Company News Industry News Technical Information