Dryer For Mining metallurgy And Chemical Industry

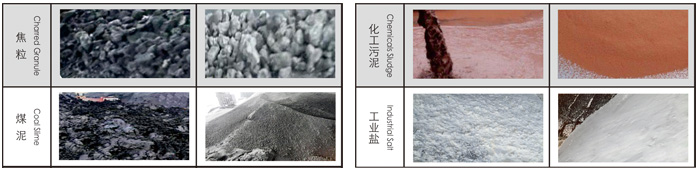

It is suitable for drying slime raw coal clean coal lignite coke blue carbon pulverized coal industrial salt iron powder gypsum tailings quartz powder bentonite sand and other materials.

Application AreaWidely used in coal chemical mining and other industries.

24 Hours Free Consultation Hotline

+86-176-3914-6338

Product Details

The production line of dryer for mining, metallurgy and chemical industry generally includes: heating system, drying host, induced draft system, dust removal system, conveying device and control system, etc.

The dryer for mining, metallurgy and chemical industry can use natural gas, steam, biomass particles, fuel oil, coal, boiler exhaust and other heat sources for heating. It has a wide range of applications and is convenient for different users to choose.

We can design a scientific and reasonable drying scheme according to the characteristics of materials, output, drying degree, site size and other requirements, so as to meet the diversified drying needs of users.

1. Negative pressure operation, good sealing and insulation effect, low heat loss, clean and sanitary site.

2. The equipment has variable speed transmission, stable operation and low failure rate.

3. The production process of the equipment is excellent, the quality is excellent, the technology is advanced and mature, and the production performance is stable and reliable.

4. The whole drying system is centralized control, high degree of automation, simple and convenient operation.

It is suitable for drying slime, raw coal, clean coal, lignite, coke, blue carbon, pulverized coal, industrial salt, iron powder, gypsum, tailings, quartz powder, bentonite, sand and other materials.

Widely used in coal, chemical, mining and other industries.

The dryer of mining, metallurgy and chemical industry has large heat transfer area, long drying stroke and high storage capacity. In the dryer, there are not only vortex motion, but also a lot of reciprocating motion. The unique mechanical anti guide material technology enables the dryer to hold a large number of materials. The hot air, materials, the guiding material system and anti guide material system in the dryer complement each other and interact with each other, forming the whole benign system. The whole drying process is harmonious and orderly, the heat energy is fully utilized, the output is greatly improved, and the effect of energy saving and consumption reduction is really achieved.

Customer Case

Dryer For Mining Metallurgy And Chemical Industry case video

- Heating Mode: coal, natural gas, oil, biomass particles, steam, boiler flue gas, blast furnace gas

- Processing Capacity: 200-1000t / D / set

- Suitable material moisture content: 20% - 50%

- Moisture content of finished product: 1% - 15%

SOLUTION

-

About +

About us Contact us -

Solution +

Sludge Dryer Steam Dryer Pulp Dryer Dregs Dryer Waste Heat Utilization Dryer Dryer For Mining,Metallurgy And Chemical Industry Auxiliary Equipment Of Dryer -

Case Video +

Sludge dryer case video steam dryer case video pulp dryer case video dregs dryer case video Waste heat utilization dryer case video Dryer For Mining,Metallurgy And Chemical Industry case video -

News +

Company News Industry News Technical Information