Introduction and comparison of four common dryers

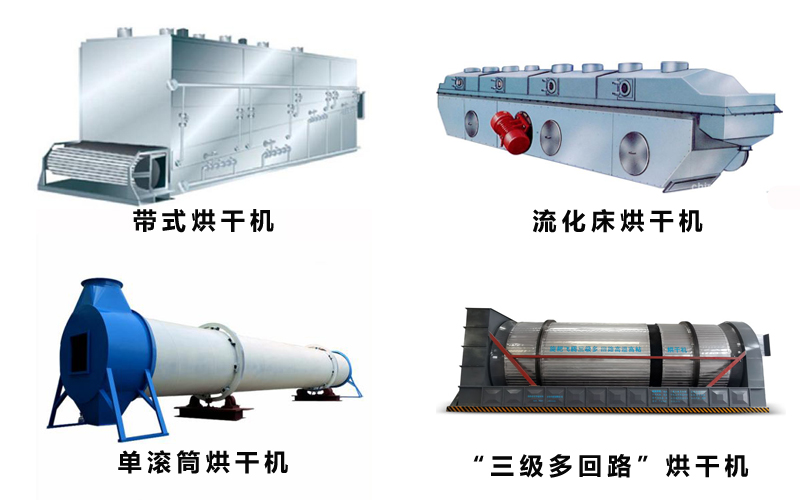

1、 Belt dryer

Working principle: the belt dryer is that the material is continuously and evenly applied on the perforated belt through the feeding room, and the product is transported through the drying area. In these drying areas, the drying gas flows through or through the wet material for drying. Each unit can be equipped with a ventilation fan and a heat exchanger. This design allows the drying and cooling temperatures to be controlled separately in different areas. Therefore, each drying chamber can be controlled independently and the drying / cooling air flow in each drying chamber can be changed. In addition, the speed of the conveyor belt can also be changed, which provides additional parameters for setting the drying time. The drying zone can be heated or cooled directly or indirectly. All heating media, such as oil, steam, hot water or hot gas, can be used. Belt dryers are ideal for drying almost all non mobile or particulate products that require low production capacity.

2、 Fluidized bed dryer

Working principle: the fluidized bed dryer is that the hot air and wet materials are evenly added into the fluidized bed chamber (with raking device) through the feeder to fully contact with the hot air. After passing through the fluidized bed chamber, the semi dry product is basically loose, which ensures the flow quality of the whole drying process and meets the drying requirements of the product. Through the volume expansion principle of the equipment, the fine powder content of the discharged air is small. The waste gas is removed by cyclone separator, bag filter and washed by water curtain filter.

3、 Single drum dryer

Working principle: the machine is mainly composed of revolving body, material lifting plate, transmission device, support device, sealing ring, etc. The dryer is a cylinder slightly inclined to the horizontal direction. Add materials from high places. High temperature hot flue gas and materials flow into the cylinder side by side. With the rotation of the cylinder, due to the effect of gravity, the material flows to the lower end. The inner wall of the cylinder is equipped with a profiling plate to remove the material, increase the contact surface between the material and the air flow, improve the drying speed and promote the material to move forward. The dried product is collected from the bottom.

4、 "Three-cylinder multiple loop" dryer

Working principle: three cylinder sets with different diameters are used to form one, two and three-stage dryers. The air volume and temperature of hot air are adjusted with the fluctuation of sludge moisture content. The air volume and temperature in the primary dryer are large, which can quickly dry the material surface. The air volume and temperature in the two-stage dryer are small, mainly drying the internal moisture of sludge. If the air volume and temperature in the three-stage dryer are small, the sludge can be fully dried again to reach the standard specified by the user.

| Events |

“three-cylinder multiple-loop” dryer |

Single cylinder dryer | Fluidized bed dryer | Belt dryer |

| Feeding requirements |

High humidity and high viscosity or loose materials can be dried to less than 15% of water content in one time regardless of the water content of the feed. It is mainly used for sludge drying and drying of high humidity and high viscosity materials |

loose materials | loose materials | It is used for drying the flake, strip and granular materials with good permeability, and for dehydrated vegetables, catalysts, Chinese herbal pieces, etc |

| Drying temperature | As long as the inlet temperature is above 120 ℃, the material can be dried to below 15% at one time | High temperature drying | Low temperature drying, single output is very small, large energy consumption | Low temperature drying, single output is very small, large energy consumption |

| Temperature control | The inlet temperature can be adjusted according to the moisture content of sludge | The inlet temperature of the whole drying process remains unchanged | The inlet temperature of the whole drying process remains unchanged | The inlet temperature of the whole drying process remains unchanged |

| Storage capacity | When drying, the material storage in the dryer is large and the output is large | When drying, the material storage in the dryer is small and the output is small | When drying, the material storage in the dryer is small and the output is small | |

| Drying cost ( on the same condition) | Low | meidum | High | High |

-

About +

About us Contact us -

Solution +

Sludge Dryer Steam Dryer Pulp Dryer Dregs Dryer Waste Heat Utilization Dryer Dryer For Mining,Metallurgy And Chemical Industry Auxiliary Equipment Of Dryer -

Case Video +

Sludge dryer case video steam dryer case video pulp dryer case video dregs dryer case video Waste heat utilization dryer case video Dryer For Mining,Metallurgy And Chemical Industry case video -

News +

Company News Industry News Technical Information